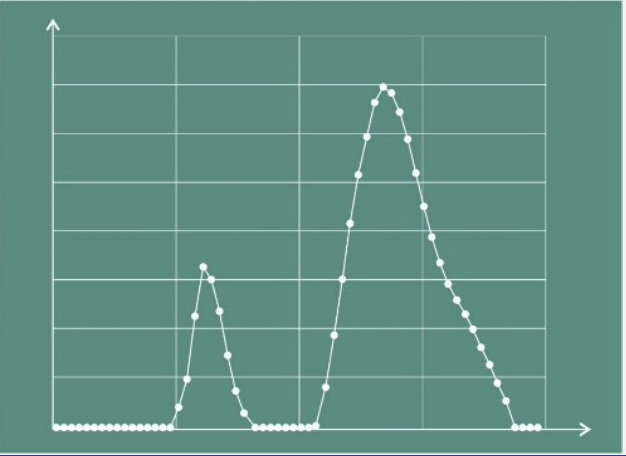

Typical particle size distribution of excipients (LH21 type):

|

PRODUCT NUMBER |

APPLICATION |

HYDROXYPROPYL CONTENT (%) |

PARTICLE SIZE |

|

HPC-LH11 |

Disintegrants mainly used to prevent tablet capping and for direct compression |

10.0-12.9% |

55μm |

|

HPC-LH21 |

Binders and disintegrants mainly used in wet granulation tablets |

10.0-12.9% |

45μm |

|

HPC-LH22 |

Regular disintegration performance, can be used when a large adhesive force is not required |

7.0-9.9% | 45μm |

RECOMMENDED FEATURES

- Chemically inert.

- Widely used in oral solid preparations.

- Used as a disintegrating agent or binder for tablets and granules in wet and dry granulation.

- Different particle sizes, different degrees of substitution, different applications.

- HPC-LH11 anti-Capping effect is the best selected models support consistency evaluation research.

SPECIFICATION

-

Executive standard: USP / Ph. Eur. / BP / IP

-

Functional use: Disintegrants for tablets and capsules, tablet binders

-

Product Category: Pharma excipient

-

CAS number: 9004-64-2

-

Packing Specifications: 25kg/drum

KEY APPLICATION

Disintegrant

The powder has a large surface area and porosity, which greatly improves the moisture absorption rate and enhances the swelling property, thereby accelerating the disintegration of the tablet, accelerating the dissolution of the drug, and improving the bioavailability.

Product special purpose

Capping problem is a typical problem in the tableting process. Many reports indicate that capping is caused by excessive die wall residues during tableting. Low-substituted hydroxypropyl cellulose can reduce the resistance of mold wall residues and demolding resistance during tablet compression.

LH-11 is a multi-fiber model, and it also has the best anti-capping effect. Its fibers are intertwined together to effectively prevent capping.

Compared with three super disintegrants (sodium carboxymethyl starch, croscarmellose sodium, Crospovidone) low-substituted hydroxypropyl cellulose has certain advantages in water absorption rate and water absorption capacity, and it will not gel, and will not appear “pockmarked” after the tableting stress is removed.

Because low-substituted hydroxypropyl cellulose is prepared by etherification of high-quality wood pulp, it is chemically inert and has high compatibility with raw materials in preparations. It is often used for cardiovascular system, digestion and in systemic medicines.

Binders

The rough particle structure has a strong mosaic effect, which can improve the hardness and gloss of the tablet, and enhance the molding eciency and effect of dicult-to-form drugs. The recommended concentration in the prescription is 5%-50%.

Food Additive

Low-substituted hydroxypropyl cellulose (L-HPC) is a low-substituted poly(hydroxypropyl) ether of cellulose. L-HPC is proposed for use as a food additive in food supplements in solid form (tablet), with a maximum use level of 20,000 mg/kg and a typical use level of 10,000 mg/kg.