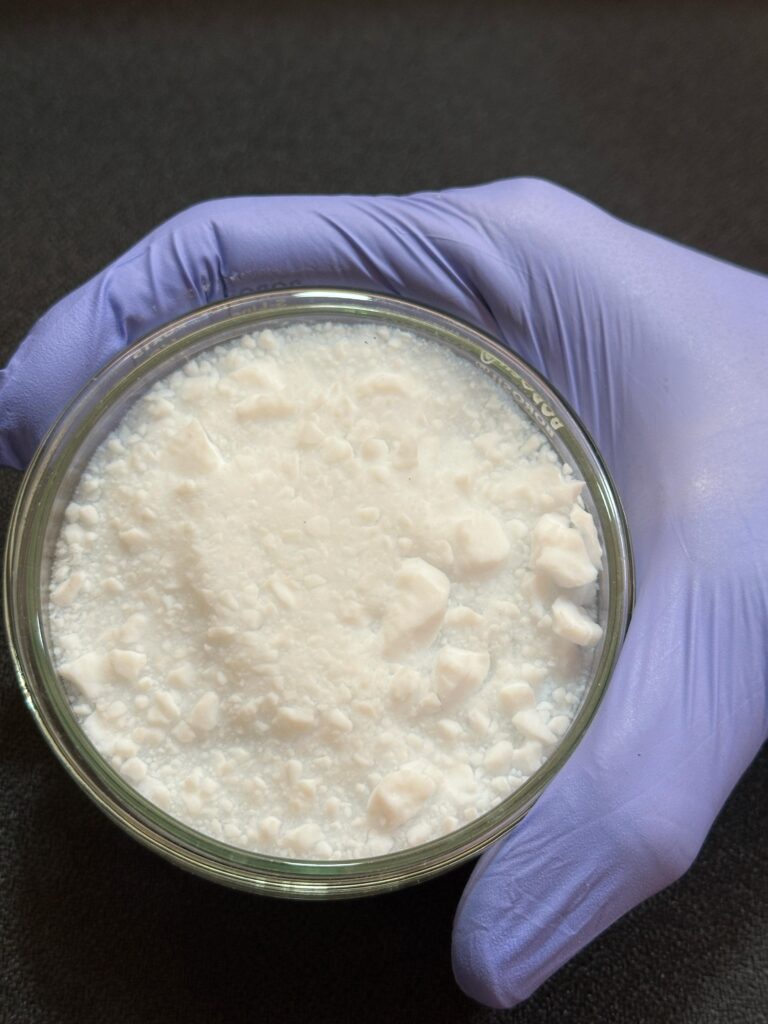

OMNISILTM 200P is a high purity amorphous anhydrous colloidal silicon dioxide for use in pharmaceutical products (tested according to USP/NF, Ph. Eur, IP, BP)

PROPERTIES

-

Free flow and anti-caking agent to improve powder properties.

-

Improves tablet properties such as hardness and friability.

-

Used as viscosity increasing agent to thicken and thixotropic liquids.

-

Desiccant for moisture-sensitive actives.

-

Improves distribution of active pharmaceutical ingredients

Designed for improved powder flow and cost efficient production of solid dosage form

SPECIFICATIONS OF OMNISIL 200P

|

Sr. No. |

Test |

Reference |

Specification |

|

1.

|

Appearance |

Ph.Eur./IP/BP/USP-NF |

A light, fine, white or almost white, amorphous powder, with a particle size of about 15 µm(Nanometer), practically insoluble in water and in mineral acids except hydrofluoric acid. It dissolves in hot solutions of alkali hydroxides |

|

2.

|

Solubility

|

USP/NF |

Soluble in hot solutions of alkali hydroxides, insoluble in water and in acid (except hydrofluoric). |

|

|

|

Ph. Eur./IP/BP |

Practically insoluble in water and in mineral acids except hydrofluoric acid. It dissolves in hot solutions of alkali hydroxides. |

|

3.

|

Identification |

||

|

4.

|

Identification – A |

USP/NF |

A deep yellow color is produced. |

|

5.

|

Identification – B |

USP/NF |

A greenish blue spot if produced. |

|

6.

|

Identification |

Ph. Eur./IP/BP |

Gives the reaction of silicates |

|

7.

|

Assay |

USP/NF |

99.0 % – 100.5 % on the previously ignited basis. |

|

8.

|

|

Ph. Eur./IP/BP |

99.0 % – 100.5 % on the previously ignited basis. |

|

9.

|

Loss on ignition

|

USP/NF |

The previously dried colloidal silicon dioxide loses NMT 2.0 % of its weight. |

|

10.

|

|

Ph. Eur./IP/BP |

<0.5 % |

|

11.

|

Arsenic |

USP/NF |

Not more than 8 ppm |

|

12.

|

pH value (1 in 30 dispersion) |

Ph. Eur./IP/BP |

3.5 – 5.5 |

|

|

pH value (1 in 25 dispersion) |

USP/NF |

3.5 – 5.5 |

|

13.

|

Loss on drying |

USP/NF |

NMT 2.5 % |

|

14.

|

Chloride |

Ph. Eur./IP/BP |

Not more than 250 ppm |

|

15.

|

Heavy metals |

Ph. Eur./IP |

Not more than 25 ppm

|

|

16.

|

Microbial enumeration tests and tests for specified microorganisms / microbial contamination Total aerobic microbial count Total combined yeast and mold count Escherichia coli and Salmonella sp. |

USP/NF

|

Not more than 1000 cfu/g Not more than 100 cfu/g Absent /1g

|

OMNISIL 200P

Colloidal Silicon Dioxide Complies to USP/NF, Ph. Eur., IP

Packaging Requirements:

10 kg paper bag with proper labeling. The paper bag is covered with “OMNISCIENT” printed polythene bag.

TAMC (total aerobic microbial count) , TYMC (total combined yeast and mould count) and Gram-negative bacteria are tested on a regular basis acc. to USP <61> and USP <62>.

Manufactured and packaged in a dedicated closed production system according to ISO 9001 : 2015.

White, fine, amorphous powder.

Typical sieve residue (Grit, 45 μm) is < 0.025 % (according to ISO787-18).

Residual solvents:

No organic solvents are used in the manufacture of above mentioned product. For this reason, constitutionally no residual solvents as cited in recent versions of the European Pharmacopoeia, (class 1, 2 and 3 or other solvents, USP chapter 467), 2008 and amendments are present in concentration about the control limits quoted in USP. For above mentioned product class 1 residual solvents are tested on a regular basis according to USP/NF: Carbon tetrachloride, 1,2 Dichlorethane, 1,1Dichlorethene, 1,1,1 Trichlorethane and Benzene.

TSE/BSE and materials of plant origin:

No raw materials of animal or plant origin (as mentioned in EMEA/410/01, current version) are used in the production process of OMNISILTM 200P. OMNISILTM 200P have not been in contact with and constitutionally do not include any material of animal or plant origin. We generally do not use any material of animal or plant origin in our production facilities. OMNISILTM 200P are not contaminated with material of animal or plant origin when they leave our production and warehouses.

Industrial Applications

- Paints and coatings

- Unsaturated polyester resins, laminating resins and gel coats

- HTV- and RTV-2K-silicone rubber

- Adhesives and sealants

- Printing inks

- Cable compounds and cable gels

Food, Feed and Cosmetics

As a food additive, it serves as an anticaking agent to avoid clumping. In supplements, food- grade fumed silica is an effective thickening, emulsification, gelling and anti-settling agent, due to its ability to form a network and hold heavier ingredients in place.

OMNISILTM 200 is suggested for use in skin care,oral care, hair care (beaches, dyes, conditioners), make-up (powder, nail polish, lipstick/lip gloss) and antiperspirants & deodorants (sticks) applications.